Digital repair process

Transparency, efficiency and quality

in every battery repair

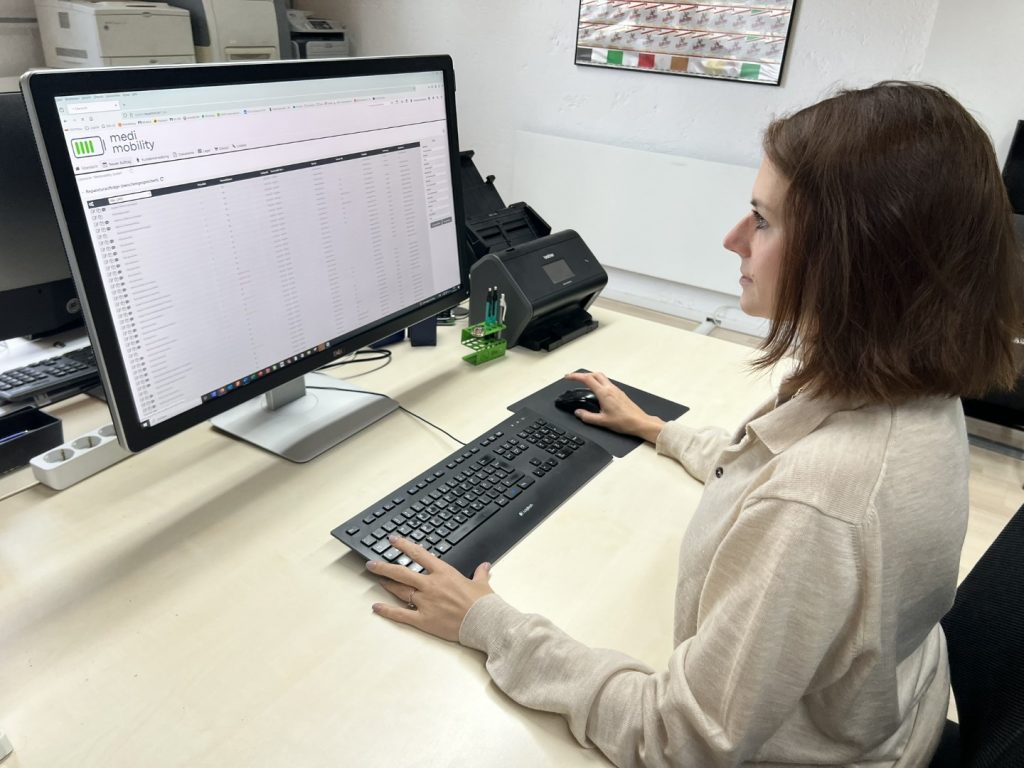

Transparent process

in real time

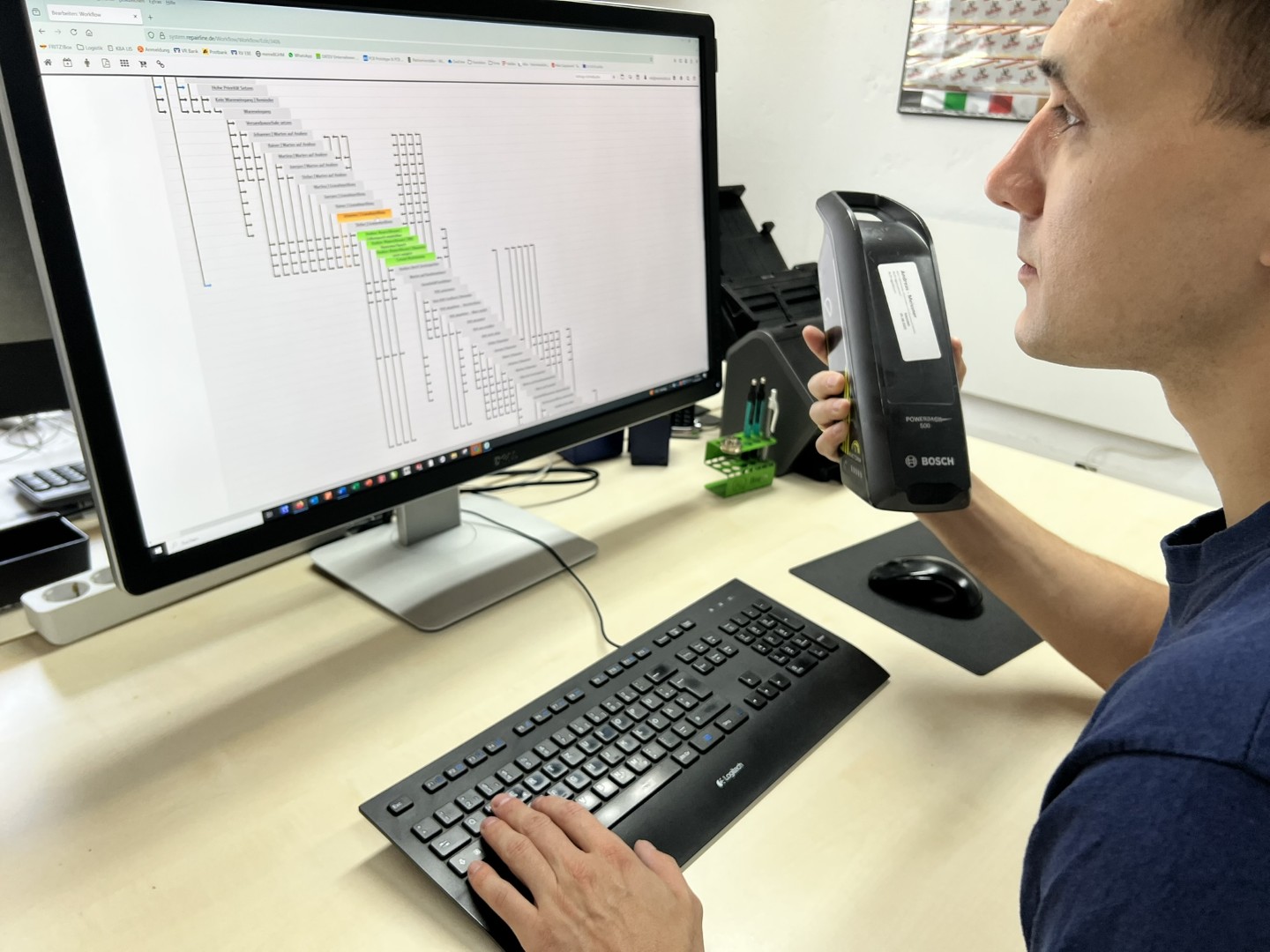

At Medimobility, we rely on a fully digitalised repair, maintenance and analysis process that makes our work faster, more transparent and more efficient. Thanks to a digital twin of our service centre, every step from order receipt to battery return is digitally mapped – without system breaks and with maximum transparency for our customers.

Our digital repair process allows customers to track the progress of their order in real time. Whether it’s analysis, spare parts ordering or repairs, all process steps can be viewed at any time. Tasks are automatically assigned to our employees, so that an employee-specific backlog is maintained and everyone knows exactly what needs to be done next.

Complete documentation

Automatic document creation

… but also individual documents, such as reminders, service notices for specific battery types, safety instructions, etc.

Direct warehouse connection

Medimobility offers the following repairs as standard. This list can be expanded at the customer’s request. The digital repair process is directly linked to our warehouse. Required spare parts are automatically removed from stock as soon as they are used in an order. This ensures accurate stock levels, faster repairs and less administrative work.

Efficient data management, evaluation and communication

All process data is stored in a structured manner and can be used for a wide variety of evaluations, for example:

You can communicate directly with the customer from each repair ticket – including sending images, test reports or other documents. This makes queries efficient and ensures fast, transparent coordination.