Battery maintenance

in E-mobility

The maintenance of energy storage systems in e-mobility makes sense for certain groups of users, such as fleet providers, fleet managers, lessees or lessors.

Battery maintenance takes place in three phases: preventive and corrective maintenance, and optimisation.

Medimobility GmbH

State-of-the-art battery storage repairs and reconditioning for business customers

Preservation of e-mobility

Batteries in e-bikes, e-scooters and e-cars consist of modular cell packs and standardised components such as the BMS. Often, only individual components are affected by defects – such as circuit boards, contacts or individual cells.

Targeted maintenance, repair or cell replacement can save resources, reduce costs and significantly extend service life. This makes ecological sense and is economically attractive – especially for high-quality or difficult-to-replace batteries.

Conclusion: E-mobility batteries are ideally suited for sustainable maintenance – a win for users, the environment and the circular economy.

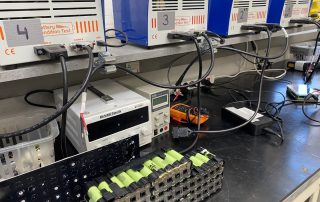

Battery analysis and battery diagnostics in e-mobility

The aim of the diagnosis is to provide a repair recommendation and to estimate the costs and duration. In addition, Medimobility can also carry out a warranty claim review for its B2B customers.

Medimobility checks the following points during a diagnosis as standard. This list can be flexibly expanded at the customer’s request.

Medimobility has also coordinated diagnostic procedures with many B2B customers, introduced customised software for analysis (especially when complex CAN systems are in use) or even developed it jointly.

Battery maintenance and repair in e-mobility

Most e-bike batteries can be repaired quickly and cost-effectively. Repair processes can be defined and standardised in advance together with B2B partners. As many customers value original spare parts, Medimobility offers storage services for these. Medimobility uses only high-quality brand-name cells for all repairs.

Medimobility offers the following repairs as standard. This list can be flexibly expanded at the customer’s request.

Medimobility has also coordinated repair procedures with many B2B customers and introduced customised software for repairs.

E-Bike

E-bike batteries are mostly based on lithium-ion technology and have a capacity of 300–700 Wh, often 500 Wh. They use 18650 or 21700 cells, combined to 36 V or 48 V. High-quality models rely on brand-name cells (Samsung, Panasonic, LG) and a BMS for charging, discharging and safety protection. The service life is around 500–800 charging cycles.

Weighing between 2.5 and 4 kg, the batteries are usually removable and take 3 to 6 hours to charge. Proper use and occasional maintenance can significantly extend their service life and improve their environmental performance.

Due to their design, bicycle batteries are ideal for repair, analysis and regular maintenance – especially for fleets, resorts and leasing providers.

Vespa / Roller / E-Roller / E-Scooter

E-scooter batteries almost always use lithium-ion technology (18650/21700 cells, e.g. Samsung, LG, Panasonic) and offer 1.5–4 kWh capacity – sufficient for a range of 40–100 km. Depending on the model, the nominal voltage is 48–72 V. High-quality batteries achieve 500–1,000 charging cycles (approx. 3–6 years) and are protected against overcharging, deep discharge and overheating by a BMS. Regular maintenance further increases their service life.

Since e-scooter batteries usually have a high voltage limit of 60 V DC, they should only be checked by qualified personnel. Repairs are particularly worthwhile here, as the components are significantly more expensive than those used in e-bikes. Regular maintenance is especially important for company fleets, delivery services and leasing providers.

Motorcycle / Electric motorcycle

Electric motorcycle batteries provide the energy for long ranges and powerful performance. They are almost always based on lithium-ion technology with 21700 or 18650 brand cells (Samsung, LG, Panasonic) and offer a capacity of 6–20 kWh. The nominal voltage is in the high-voltage range from 72 V to over 300 V. High-quality batteries achieve 800–1,500 charging cycles, corresponding to a service life of 5–10 years – controlled and protected by an integrated BMS.

As electric motorcycle batteries are well above the 60 V high-voltage limit, they may only be inspected by qualified personnel. The high-quality components make repairs particularly attractive. Regular maintenance is also worthwhile for B2C customers.

L7e vehicles / Car / Electric car / Electric vehicle (EV)

Electric car batteries range from compact to highly complex. They are the heart of modern electric vehicles and have a decisive influence on range, performance and charging speed. Most electric car batteries are based on lithium-ion technology, often with NCM or NCA cell chemistry, in the form of pouch, prismatic or cylindrical cells (e.g. 18650 or 21700).

Typical performance characteristics:

- Capacity: from 10–20 kWh for compact L7e vehicles to 60–120 kWh for full-size cars

- Voltage: mostly 300–800 V high-voltage systems

- Cycle life: approximately 1,000–3,000 full cycles, depending on chemistry, usage and temperature management

- BMS monitors and controls charging and discharging processes, balancing and safety systems.

Light electric vehicles in the L7e class (e.g. Microlino, Renault Twizy) use compact, modular batteries that are much easier and cheaper to repair – for example, when replacing the BMS or cells. Mid-range and luxury cars, on the other hand, use large high-voltage traction batteries (hundreds to thousands of cells, complex cooling, safety-critical electronics), which require close cooperation with the manufacturer.

Maintenance of these vehicles is crucial, as the battery accounts for up to a third of the vehicle’s value. Repairs and analyses are also possible, but require specific manufacturer expertise.

Battery maintenance in e-mobility

Maintenance of energy storage systems in e-mobility is advisable above a certain size or quantity (e.g. as a fleet provider, fleet manager, lessee or lessor).

Battery maintenance can be broadly divided into preventive maintenance, corrective maintenance and optimisation. At Medimobility, corrective maintenance tasks fall under the heading of repairs.

Preventive maintenance services:

Optimisation services:

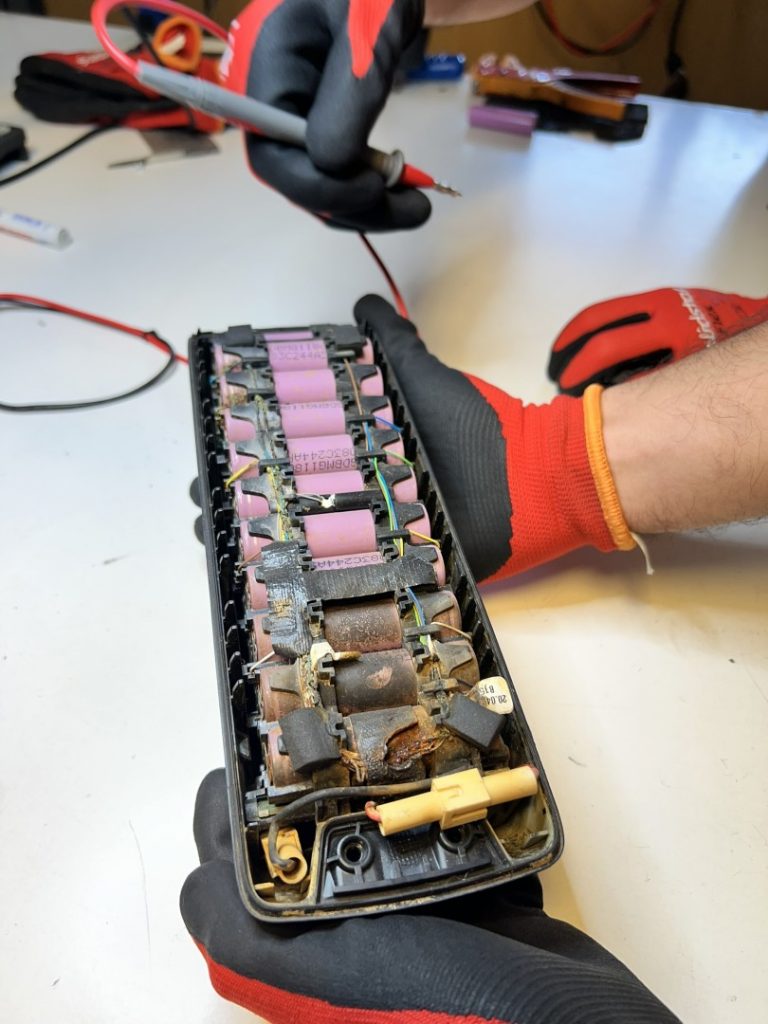

Other applications

Lithium-ion batteries are everywhere in our everyday lives, not just in the field of electric mobility. These batteries also need to be analysed, maintained and repaired, otherwise things could soon look like this:

Industry & Trade

Medicine & Specialised Technology

E-mobility

Secure & legally compliant battery logistics

The transport of lithium-ion batteries is subject to strict legal requirements. We have all the necessary training and certifications, including ADR training, as well as certified dangerous goods contracts.

Whether it’s a single battery by parcel, entire pallets, on-site collection or shipping – we guarantee legally compliant, safe and efficient logistics for private and business customers. This means you can have your battery transported without hesitation – from sending it in for repair (link), maintenance (link) or analysis (link) to safe return delivery.